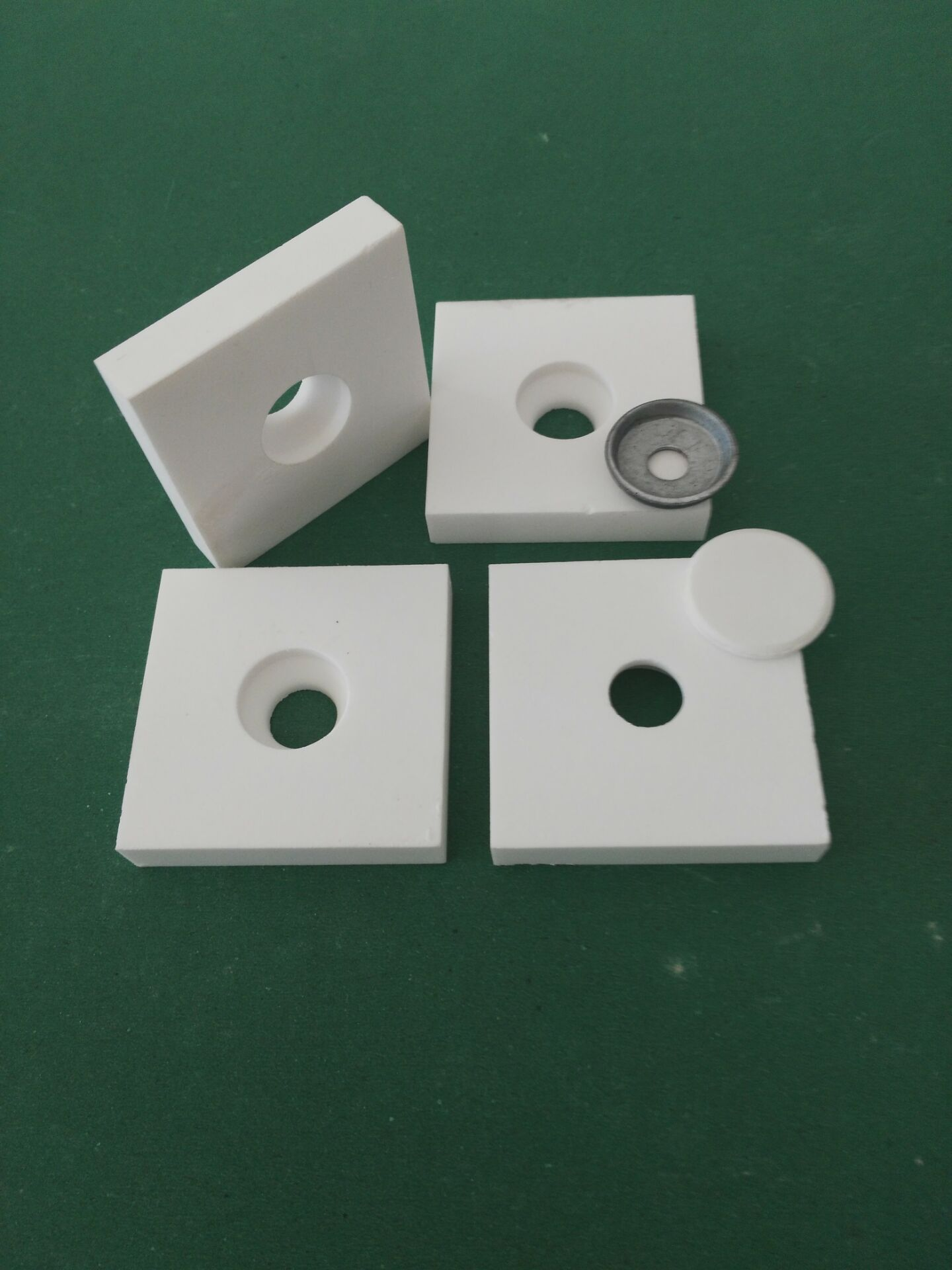

Wear-resistant ceramic lining plate is a material based on alumina (AL2O3), supplemented by other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal handling, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment in cement, port and terminal enterprises.

Compressive strength ≥850 Mpa

Fracture toughness KΙC ≥4.8MPa·m1/2

Bending strength ≥290MPa

Thermal conductivity 20W/m.K

Thermal expansion coefficient: 7.2×10-6m/m.K

Molding process: formula—grinding—forming—sintering—grading—shipping

Wear resistance: Alumina corundum ceramics, the hardness reaches above HRA85, the wear resistance is 271.5 times that of steel;

Impact resistance: The toughened ceramic formula ensures that the ceramic is not easily broken. The unique spherical design and high-quality buffer layer can resist the impact of large materials;

High temperature resistance: can operate at 0℃-250℃ for a long time;

Acid and alkali resistance: The rubber adopts a new formula of acid and alkali resistance rubber, which can resist weak acids and weak alkali;

Anti-falling: The ceramic rubber steel plate is vulcanized in one piece, and the combination is very strong; each piece of ceramic has penetrating bolts passing through the bottom steel plate, and is firmly welded for double insurance;

Easy to install and replace: It is provided with a whole lining board, which facilitates replacement and installation and reduces after-sales service;

Reduce maintenance: Super wear resistance greatly reduces the frequency of maintenance, saving costs and labor.

客服1

客服1